Ceramic and Composite Materials Center (CCMC)

University of New Mexico (lead) and Rutgers, The State University of New Jersey

A National Science Foundation Industry/University Cooperative Research Center since 1999

Partner Institutions:

- Sandia National Laboratory

- Los Alamos National Laboratory

- Army Research Laboratory

The development of leading-edge ceramic and polymer/ceramic composite materials and processes provides the technical base to enable the United States to compete successfully in the global marketplace

|

Center Mission and Rationale

The mission of the Ceramic and Composite Materials Center (CCMC) is to develop new interdisciplinary technologies to make the United States more competitive in ceramic science and engineering, and to transfer these technologies to its industrial members in order to foster the development of competitive, reproducible ceramic and polymer/ceramic composite materials for advanced, high-performance systems.

The CCMC mission recognizes the great opportunity afforded by the formation of a multi-university science and engineering center that has both a strong chemical synthesis component and an equally strong processing capability. This combination will provide the intellectual leadership to meet future ceramic and polymer/ceramic composite science and technology needs of our member companies. The focus is to develop a technology base that will lead to the development of competitive, reproducible ceramic products that:

- Can be manufactured by robust, high-yield, and environmentally friendly processes

- Contain chemically and physically tailored microstructures

- Are cost efficient to manufacture

- Can be tailored to specific applications

- Are based on the best innovative science, technology, and engineering practices.

|

The following actions and activities enable the Center to accomplish its mission:

- Close interaction between the researchers at UNM and Rutgers to develop an interdisciplinary research program in materials and processing with emphasis on developing new areas of ceramic technology such as polymer/ceramic composites and control of structure and porosity on small length scales.

- Collaborative research alliances with outstanding researchers from other universities to bring in talent and expertise that complement the Center's research interests.

- Development of new science, technology, and novel concepts to overcome the underlying problems common to ceramic and polymer/ceramic composite materials, products, and processes.

- Serving as an in-depth, expert resource for ceramic and polymer/ceramic composite science and technology.

- Transfer and exchange of knowledge/technology and inventions to the Center's industrial members and Federal Government supporters.

- Significant contribution to ceramic education by training and educating students, including providing exposure to industrial technology and industrial research procedures.

- A focal point for networking in ceramic and allied areas of science and technology for exchange of ideas and to identify global needs and opportunities.

Research Program

The Center's cooperative program research projects are integrated into five specific research areas that cover a broad spectrum of ceramic and polymer/ceramic composite science and engineering, as described below.

-

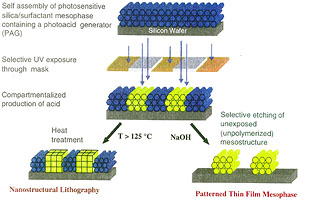

Sol-Gel Synthesis and Processing -- Center researchers are exploring new sol-gel precursor chemistries and new processing strategies with the following goals: (1) Development of rapid simple approaches to the formation of dense multicomponent oxide films for non-volatile memories, ion transport membranes, and superconductors; (2) Integration of sol-gel processing with self-assembly, lithography, and rapid prototyping techniques to create highly ordered nanoporous and nanocomposite materials for applications such as fluidic or photonic microsystems, membranes, hard-coats, and catalysts; (3) Development of theory and simulation methods to understand self-assembly and the properties of self-assembled porous and composite media.

-

Powder Processing --The successful development of useful ceramic components for applications varying from thin laminar structures for microelectronic applications to monolithic structural ceramics depends on the ability to uniformly and efficiently mix ceramic raw materials in the form of dry powders, slurries, suspensions, and composites with polymer binders and other additive chemicals. Both modeling and experimental methods are used to understand the mixedness of multicomponent particulate mixtures. In order to improve compaction behavior of dry powders, the important factors that affect the closure of large residual pores in compacts made from spray-dried powders are under study. The effect of particle properties and packing characteristics on the rheological behavior of blended oxide particles in the form of pastes is under investigation.

-

Vapor Phase Synthesis --The Center has had a long involvement in the use of aerosol assisted vapor phase synthesis (AAVS) and conventional metal/organic chemical vapor deposition techniques to synthesize powders and films with controlled compositions, porosities, and morphologies. The AAVS technique currently is being exploited to produce nanophase or nanocomposite materials. An understanding of the relationships between composite particle chemical characteristics, powder processing parameters and performance related properties is critical. Nanocomposite powders with controlled stiochiometry offer lower sintering temperatures and the ability to synthesize powders where it is difficult to maintain compositional control using traditional solid-state synthesis techniques. Although high-power plasma spheroidization of ceramic particles at atmospheric pressure is an old art, Center researchers have now demonstrated that a low power, microwave- (MW) generated plasma can be used to modify the morphology of refractory particles at atmospheric pressure. This new technique enables irregularly shaped refractory oxide particles to undergo melting with concomitant spheroidization. The operational parameters for controlling particle size and morphology are being studied. This MW-generated plasma enables the formation of spherical particles over a wide range of materials and compositions.

-

Structural Ceramics -- Two important issues in the development of commercially useful structural ceramic materials are being addressed. One of them is an improved method for the direct bonding of ceramic and metals. The objective is to obtain strong, electrically/thermally conductive, creep resistant bonds between ceramic and metal materials at lower processing temperatures compared to conventional direct bonding techniques. In order to be successful, the Center researchers study the direct bonding mechanism(s), including the relationships between processing conditions, interfacial reactions and bond strength.

The second issue is a better understanding of the chemical/mechanical polishing (CMP) of ceramic materials to achieve a very high degree of planarity, a critical requirement in many end-use applications. This issue is being studied using both aqueous and non-aqueous oxide polishing slurries on selected oxide and non-oxide ceramics. The pH of the abrasive slurry is a key to material removal using CMP, and its effect on the efficacy of polishing is being determined.

-

Electronic Ceramics and Composites -- As the electronics industry moves to smaller and smaller devices and systems, multifunctionality increases in importance. One way to achieve multifunctionality is to adopt a multilayered approach whereby thin layers of ceramic with desired electrical properties are plied together and fused into a monolithic device. In order to develop useful sintering models, a finite element method is used to develop a viscoelastic model for the shape distortions and stresses that occur during the sintering. Free sintering and sinter-forging experiments are used to monitor the axial and radial strains. The experimental sintering data are fitted to the predicted sintering curves to generate the parameters of the model.

A major effort directed at improved thermal management materials for the microelectronics industry constitutes the development of improved thermally conductive, insulating fillers for polymer composites. This is part of a general thrust to prepare polymer/ceramic composite materials that can be formed under low processing temperatures and still exhibit useful electronic and physical properties. One research area emphasizes the use of vapor phase techniques to prepare spherical particles of boron nitride that have thermal conductivities approaching those of the commercial BN powders. Another research area consists of modification of the surface of BN particles to improve their compatibility with organic polymers.

The recent advances in telecommunications and portable information technologies, and the decision to move away from gasoline-based power supplies for future vehicles for personal and public transportation, place the spotlight on the development of more efficient fuel cells and batteries for both small and large energy applications. Research programs are in place to develop novel materials and catalysts designed to boost the efficiency of the next generation of fuel cells. One program emphasizes the development of non-platinum electrocatalysts for direct methanol fuel cells. Another program studies the structural/property relationships important to the development of improved cathode materials for rechargeable lithium batteries.

Center Headquarters

Ceramic and Composite Materials Center

Farris Engineering Center, Room 203

The University of New Mexico

Albuquerque, NM 87131

Tel (505) 277-2833 * Fax (505) 277-1024

Homepage: www.unm.edu/~ccmc/

Center Director: Dr. Abhaya K. Datye

cmem@unm.edu

Co-Director: Dr. Dale E. Niesz

(732) 445-5900 * niesz@alumina.rutgers.edu

Co-Director: Dr. William J. Kroenke

(505) 277-6824 * yonder@unm.edu

Center Evaluator: Dr. James R. Buckmelter

(505) 292-2443 * jbuckmel@unm.edu

Center Evaluator: Dr. S. George Walters

(910) 329-0824

NSF 01-168i