Center for Advanced Processing and Packaging Studies (CAPPS)

North Carolina State University (lead institution)

A National Science Foundation Industry/University Cooperative Research Center since 1987

Partner Institutions:

- The University of California at Davis

- The Ohio State University

Novel food processing and packaging research will lead to improved product quality and safety while enhancing the nutritive value of food

|

Center Mission and Rationale

The Center for Advanced Processing and Packaging Studies conducts industrially relevant research directed at developing methods and technologies for the safe production of marketable, high-quality aseptic and refrigerated extended shelf-life products. A number of new emerging technologies - including continuous flow aseptic, ohmic heating, pulsed electric field, radio frequency, high pressure, and ultra-high-temperature processing - are expected to revolutionize food industry practices in the 21st century. The Center for Advanced Processing and Packaging Studies (CAPPS) has a broad scope of research focused on investigating these new and novel technologies. With the combined resources and research efforts of North Carolina State University, the University of California at Davis, and The Ohio State University, the center is a national resource for the investigation and implementation of novel food processing and packaging technologies. The center provides the framework to secure the best scientists from all over the country to work with industry in conducting research to implement and assist in the commercialization of these new technologies.

Research Program

CAPPS supports research that provides the knowledge to:

- Assure safety of aseptic and extended shelf-life products

- Characterize emerging and commercial sterilization and pasteurization processes

- Enhance the integrity and functionality of aseptic and extended shelf-life packaging.

|

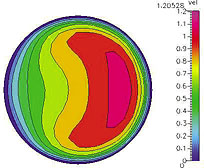

The Center employs an interdisciplinary approach that relies on engineering, microbiology, and chemistry to meet these objectives. Engineering studies focus on properties, kinetics, process evaluation, validation, modeling, and design. The opportunities for two-phase (solid-liquid) processing present special challenges. The slowest heating point in the fastest moving particle dictates the minimum thermal treatment. Factors that influence temperature in the particle include: carrier fluid flow rate and properties; particle population, properties and size; type and rate of heat transfer; and particle/fluid residence time distributions. CAPPS has developed new techniques to measure thermal properties of fluids and particles at high process temperatures and techniques to measure residence-time distributions. Ongoing research uses Magnetic Resonance Imaging (MRI) and other techniques to measure the temperature history of a particle's interior as it moves through a thermal system. The engineering challenge of developing rapid, non-chemical, cost-effective methods for on-line package sterilization continues as well. Other packaging research areas include leak detection, rapid sealing, and rapid nondestructive testing of seals.

CAPPS supports microbiology projects that aim to achieve and maintain product and package sterility and to document sterility in order to validate packaging machinery sterilization. The goal is to ensure the microbiological integrity of the finished products. Other projects include production, recovery, and documentation of the resistance of biological indicators (bacterial spores) and the mechanisms of spore inactivation. The Center's microbiologists and engineers have collaborated on projects to develop and evaluate alternative procedures to sterilize packaging materials and equipment, to understand inactivation kinetics and mechanisms in continuous thermal processes, and to develop methodologies for sterilization validation of surfaces and particulate matter.

|

Aseptic technology poses chemical challenges prior to and during processing. Fundamental investigations are necessary to ensure that the applied result is attractive and of high quality. CAPPS supports projects that deal with product quality considerations relating to color, texture, flavor, particulate integrity, and nutritional attributes. Reaction chemistry at high temperatures, high pressures, and/or high electrical frequencies and kinetic studies to predict properties are also under active investigation. Related projects range from investigations on colloidal stability of aseptic or extended shelf-life products, including shelf-life prediction studies, to enzyme stability and inactivation under high-temperature, short-time processing conditions. Interactions of packaging materials with critical quality constituents are also part of this effort. Studies on physical attributes include texture, thermal characteristics of particulates, and techniques to measure the physical properties of fluids at high temperatures. CAPPS projects also deal with generic issues expected to improve the quality of these novel processed and packaged products.

Center Research Facilities

An aseptic pilot plant is housed in the Department of Food Science at North Carolina State University with state-of-the-art aseptic processing and packaging equipment. Current processing units include direct heating/vacuum cooling (steam injection) and indirect heating/cooling (tubular, plate, and scraped surface heat exchangers). Paper-foil laminate aseptic packaging, shrink-wrap and boxing facilities are available. Complementary facilities at the University of California, Davis include MRI facilities for flow visualization, rheological properties and sensory analysis, and a complete line of membrane separation technologies that complement many processing projects. The Ohio State University site has integrated pulsed electric field, ohmic, and high-pressure processing units along with an aseptic packaging pilot plant.

In addition to the facilities at these CAPPS sites, research is conducted at many other U.S. universities. Since the inception of the center, projects have been funded at Michigan State University, North Carolina A&T, Indiana University, Purdue University at Fort Wayne Campus, Rensselaer Polytechnic Institute, the University of Illinois at Urbana-Champaign, University of Rochester Medical Center, and the Virginia Polytechnic Institute and State University. The scientific knowledge and laboratory facilities of these academic institutions extend and enhance the overall program of CAPPS.

Center Headquarters

Center for Advanced Processing and Packaging Studies

Department of Food Science

College of Agriculture and Life Sciences

North Carolina State University

Box 7624

Raleigh, NC 27695-7624

Tel (919) 515-2951 * Fax (919) 515-4694

Homepage: www.cals.ncsu.edu/food_science/capps.html

Managing Director and NCSU Site Director: Dr. Kenneth R. Swartzel

ken_swartzel@ncsu.edu

Communications Specialist: Ms. Paula Pharr

paula_pharr@ncsu.edu

UCD Site Director: Dr. Sharon Shoemaker

Tel (530) 752-2922 * Fax (530) 752-6578

spshoemaker@ucdavis.edu

OSU Site Co-Director: Dr. Sudhir K. Sastry

Tel (614) 292-3508 * Fax (614) 292-9448

sastry.2@osu.edu

OSU Site Co-Director: Dr. Steven J. Schwartz

Tel (614) 292-2934 * Fax (614) 292-4233

schwartz.177@osu.edu

NSF 01-168nn